Machining, Welding, Painting, Assembly and Turnkey Solutions

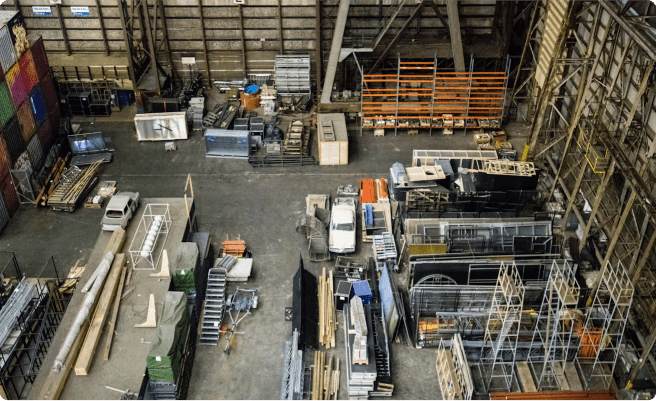

Machine Park Overview

Forte delivers high-precision solutions in machining and the energy sector. Our strong CNC machine park handles large-scale components. In addition to machining, we provide welding, painting and assembly for finished products. Our priorities are reliability, precision, and on-time delivery. We have high tonnage and micron-level precision machining capacity with a wide range of horizontal and vertical CNC machines and boring mills. Our 5-axis simultaneous machining capability ensures flexibility from prototype to mass production. We offer industrial reliability for heavy industry and energy sector needs.

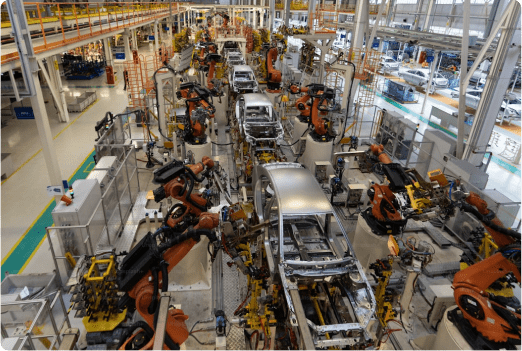

Welding, Painting & Assembly

We specialize in transforming ideas into tangible products through advanced manufacturing techniques. Our team of skilled engineers and technicians utilize state-of-the-art equipment to offer services ranging from custom design and prototyping to full-scale production. We pride ourselves on our ability to tackle complex projects and deliver solutions that exceed expectations.

Project-Based Manufacturing & Forte Advantages

Quality is at the heart of everything we do. We adhere to the highest industry standards, maintaining certifications like ISO 9001:2015 to ensure every product meets rigorous quality control criteria. Our dedication to continuous improvement and customer satisfaction drives us to deliver exceptional results on every project.

Companies who trust in us

Utilities

Industrial design and engineering come together for a variety of products and tools specifically manufactured for use by skilled workers and technicians in the field.

Assembly

Our patent-pending design is second-to-none. Pole trailer accessories fit on to trailer beds and secure everything from cables to bolts. The result - protection for both workers and the equipment they require in the field.

FAQ

What products and services does your company provide?

We specialize in manufacturing high-quality industrial components and machinery parts for a variety of industries, including automotive, aerospace, and energy sectors. Our services include product design, prototyping, mass production, and after-sales support to ensure that we meet all of your manufacturing needs.

Can you customize products to meet our specific requirements?

Yes, we offer custom manufacturing solutions tailored to your unique specifications. Our experienced engineering team works closely with clients to develop custom designs, materials, and finishes to ensure the final product meets all functional and aesthetic requirements.

What is your typical lead time for production and delivery?

Our standard lead time ranges from 4 to 6 weeks, depending on the complexity and quantity of the order. We strive to meet your timelines and can often accommodate expedited production schedules upon request. Please contact us to discuss your specific needs.

What quality assurance processes do you have in place?

Quality is our top priority. We are ISO 9001:2015 certified and adhere to strict quality control protocols throughout the manufacturing process. This includes rigorous inspections, testing procedures, and compliance with industry standards to ensure that every product meets or exceeds customer expectations.